In-Booth Presentations & Honorable Mentions

2025 Exhibitor In-Booth Presentations

The OMTEC Advisory Board selected 12 companies to deliver an in-booth presentation at OMTEC 2025.

You can find the winners below.

Please scroll down the page for the list of 19 honorable mentions.

Below you’ll find a list of the 19 honorable mentions.

These companies were not selected to deliver an in-booth presentation, but their abstract submissions warrant an honorable mention. The selection process is always challenging for the board…there are countless topics of importance and we invite you to peruse the subjects below and contact the companies directly for more information. We extend our sincere thanks to these companies for supporting pertinent knowledge building for the orthopedic OEM community.

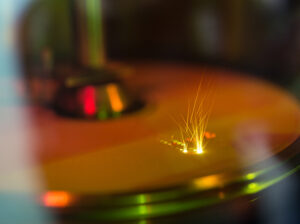

The Critical Role of Tool Surface Finish in Orthopedic Device Manufacturing

In orthopedic manufacturing, achieving an optimal tool surface finish is essential for producing high-precision implants and surgical instruments. Surface finish directly impacts cutting performance, wear resistance, and the quality of machined components, influencing factors such as dimensional accuracy, surface integrity, and biocompatibility. Poor tool surface finish can lead to excessive friction, burr formation, and material contamination, compromising both manufacturing efficiency and patient outcomes. Advanced grinding and polishing techniques, combined with precision CNC machining, enable superior surface finishes that extend tool life, enhance process stability, and ensure compliance with stringent medical industry standards. This presentation explores the relationship between tool surface finish and orthopedic device quality, highlighting best practices for optimizing machining processes to improve performance, durability, and safety in medical applications.

X3 Fiber: Expanding OEM Opportunities in Biomaterial Implants

Arctic Biomaterials – Booth 847

Material limitations, high production costs and complex manufacturing processes have historically constrained the development of bioresorbable implants. The innovative X3 Fiber composite overcomes these challenges by offering a high-strength, fully resorbable biomaterial now accessible to orthopedic companies. Whether your company specializes in orthopedics, dental or trauma implants, X3 Fiber creates new opportunities for durable, bioactive implants without traditional limitations. But how easily can it be integrated into your existing production? This presentation explores the mechanical properties, manufacturability and bioactivity of X3 Fiber, demonstrating its potential for load-bearing applications. Additionally, it examines key considerations for integrating X3 Fiber into existing production processes and cost efficiency. Discover X3 Fiber’s applications and learn how your company can enter the biomaterial implant market.

Optimizing LPBF with Variable Layer Thicknesses for Large Joint Production

The demand for high-quality, cost-effective orthopedic implants is surging. Laser Powder Bed Fusion (LPBF) additive manufacturing offers a promising solution, but its potential is often hindered by long processing times and high material costs. In this presentation, we will unveil a groundbreaking approach to optimize LPBF for joint replacement production. By strategically varying layer thickness across different regions of the implant, we have achieved a significant 34% reduction in processing time without compromising mechanical properties or geometric accuracy. This innovative technique not only accelerates production, but also minimizes material waste and lowers overall costs. Join us to discover how this exciting, transformative approach is set to revolutionize the future of orthopedic implant manufacturing.

Advancing Metals for Orthopedics: R&D Highlights from Fort Wayne Metals

- Absorbable magnesium alloys: FWM has developed nutrient metal alloys that provide structural support and harmlessly absorb into the body. Available alloys, sizes and properties will be highlighted with commentary on designing with magnesium.

- Nickel-free Superelastics: Superelastic Nitinol has found widespread use in bone staples, but potential for nickel release often limits its use in other anatomies. FWM has developed a beta titanium alloy capable of significant superelasticity which could serve in patients and applications where Nitinol can’t go.

- High Strength and Stiffness: New materials and new processes in established alloys can deliver strength, stiffness and fatigue properties in bar products not previously possible.

Characterization of Particles Released from Orthopaedic Implants

The adverse clinical impact of metallic and polymer particles released from orthopaedic implants post-surgery (wear debris) is well-known. More recently, with the increasing use of additive manufacturing (3D printing) for the production of metallic implants, the potential risks associated with unfused (loose) material within complex/porous structures are of concern. This presentation describes techniques for the study of particles generated during wear testing and unfused/loose particle shedding. Such techniques are also used to identify anomalous particles/contaminants from the implant manufacturing process. Depending on the particle sizes, which usually lie in the range of 0.1 – 1000 microns, Optical Microscopy and/or Scanning Electron Microscopy coupled with Image Analysis Software are used for counting and sizing particles along with the visualization of their morphologies. Energy Dispersive X-ray Analysis (EDA), FTIR, and ToFSIMS are used for compositional analysis.

Overcoming Additive Manufacturing Challenges with Advanced Powder Analysis

Additive manufacturing is a powerful and promising technique for manufacturing medical devices; however, it introduces new challenges such as mechanical failure. One of Lucideon’s clients faced periodic cracking in components printed at their facility, but they could not identify the root cause within their processing parameters. Leveraging Lucideon’s expertise in additive manufacturing, analytical testing laboratories and expertise in powder, our team pinpointed the root cause as the quality of the recycled powder. Lucideon’s team provided actionable recommendations, including refining powder handling processes, recycling programs and in-line process settings to prevent recurring issues. Our solution enabled the client to confidently produce high-quality AM components, reduce scrap costs and ensure reliability in end-use applications. This case study highlights Lucideon’s ability to solve complex additive manufacturing challenges and drive manufacturing innovation.

Novel Surface Chemical Characterizations to Advance Osteointegration

Hydroxyl groups are utilized on medical implants to enhance osseointegration. Nobel Biocare approached Lucideon to address a specific challenge: develop a novel method to quantify the surface concentration of hydroxyl groups on implants. Lucideon developed a novel methodology to accurately quantify hydroxyl groups while distinguishing them from other functional groups. This method enabled Nobel Biocare to determine which method achieved the highest hydroxyl group concentrations, offering invaluable insights for product R&D. Lucideon’s work directly supported Nobel Biocare in creating products designed for improved osseointegration. This innovation not only gave the client a competitive edge but also contributed to better patient outcomes. This case study highlights Lucideon’s critical role in developing novel methods to drive orthopaedic innovation and improve patient care.

Sterilization Validation Testing of Orthopedic Devices

Sterilization validation is a critical component of quality assurance in the medical device industry. It ensures that sterilization processes consistently achieve the required level of microbial inactivation, safeguarding product safety and regulatory compliance. This presentation will outline Lucideon’s approach to sterilization validation, focusing on key principles, regulatory expectations and practical methodologies. The validation process involves defining acceptance criteria and designing robust validation studies. Critical aspects such as biological indicators and cycle development will be discussed to highlight best practices in validation execution. This case study gives valuable insight into a deeper understanding of how to design and execute an effective sterilization validation program, thus ensuring that processes remain efficient, reproducible and compliant with global standards.

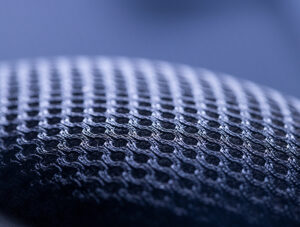

Tumble Finishing and Polishing for Orthopedics Explained

Mass Finishing Inc. (MFI) – Booth 926

Achieving a smooth finish on additively manufactured parts is highly desirable for orthopedic applications. There are many solutions, from simple hand sanding and polishing to highly automated and chemically accelerated methods. Tumble finishing is a hands-free method with many benefits, including creating a perfect isotropic finish on the outside and some internal surfaces of parts. Utilizing various shapes and compositions of tumbling media, manufacturers can achieve a mirror polish in a matter of hours on parts. This presentation will look at case studies for applications where surface finishing requirements are critical. We will also discuss the best practices and the advantages and disadvantages of various types of tumbling equipment. What are the limitations of tumbling methods for surface finishing? The discussion will provide answers and spark new ideas and possibilities for manufacturers.

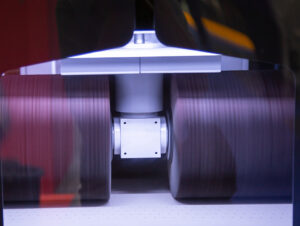

Orthopedic Parts Production: The Hybrid Manufacturing Breakthrough!

Mikron Corp. Monroe – Booth 314

Discover the future of shoulder implant production through our groundbreaking hybrid manufacturing strategy. This innovative approach, developed by MIKRON TOOL in collaboration with leading machine builder DMG MORI and cutting oil producer MOTOREX, combines cutting-edge chip removal techniques with state-of-the-art additive manufacturing. Our unique process not only enhances precision and efficiency, but also opens new possibilities in orthopedic components manufacturing. Join us as we unveil the potential of this hybrid method, designed to revolutionize the industry. Be prepared to be intrigued and inspired by the next big leap in medical technology.

A New Frontier for Sleeve Anchors

This presentation will provide a performance comparison among different sleeve anchors—V, W, O and I shapes—used in sports medicine procedures. It will focus on knot pull, anchor displacement and bone stock removal and highlight a new active suture for such anchors that promotes osseo and soft tissue regeneration.

Navigating Uncertainty: How Orthopedic OEMs Can Adapt to a Shifting Market

Orchid Orthopedic Solutions – Booth 507

The orthopedic market has long been a space for steady, predictable growth, but the past 3 to 5 years have disrupted expectations. OEMs now face tighter margins, rising costs and increased pressure to innovate while also reducing expenses. Traditional strategies, like leveraging operational efficiencies and global sourcing, are no longer enough. To maintain market position, OEMs must embrace new strategies and new technologies like additive manufacturing. At the same time, shifting global trade policies, tariffs, tender requirements and sustainability targets—including Net Zero commitments—are reshaping market access. To stay competitive, OEMs must rethink their strategies, optimize supply chains and prepare for a future where sustainability and global market dynamics shape success. This session explores the key challenges and opportunities orthopedic OEMs must consider to thrive in an unpredictable landscape.

Inner Barrier Considerations for Usability

Packaging Compliance Labs – Booth 916

Sterile packaging plays a critical role in maintaining product sterility and ensuring aseptic presentation in the orthopedic industry. The inner barrier of sterile packaging serves as the final protective layer, preventing microbial contamination while enabling efficient aseptic transfer. Key considerations for inner barrier design include packaging types (sterile or protective layer), material selection, ease of opening features, particulate generation, labeling/communication and compatibility with sterilization methods. Furthermore, the peel-ability and opening mechanisms must facilitate aseptic presentation while minimizing contamination risks. With input from healthcare professionals, this review explores these considerations to optimize sterile packaging design specific to the inner barrier, ensuring regulatory compliance and enhancing patient safety.

Culture as a Competitive Edge

Phillips Precision Medicraft – Booth 413

World-Class Orthopedic Manufacturing Through Cultural Transformation – Experience how cultural transformation drives manufacturing excellence in orthopedic device manufacturing. Through Phillips Precision Medicraft’s journey, discover the powerful symbiosis between organizational culture and manufacturing performance. Learn how strategic cultural development directly enhances product quality, accelerates innovation and optimizes operational efficiency. We’ll review real-world applications and quantifiable outcomes, including a notable case study featuring the “Zabo Project,” where cultural emphasis on innovation and problem-solving led to a breakthrough solution that resulted in a 25% cost reduction, improved quality control and shortened lead times. This example illustrates how cultural excellence translates into tangible manufacturing outcomes. This presentation reveals proven methodologies for leveraging cultural excellence as a catalyst for achieving world-class manufacturing outcomes.

Tariffs and Nearshoring: Strategies for a Resilient Supply Chain

In recent years, the trend of nearshoring production to North America has gained significant momentum. This presentation explores the key drivers behind this shift, including geopolitical tensions, supply chain resilience, rising labor costs in Asia, technological advancements and environmental sustainability goals. We will discuss the impact of new tariffs on Asian and Mexican goods, examining how these tariffs influence the cost/benefit analysis of nearshoring. Additionally, we will assess whether nearshoring remains a viable strategy despite these challenges, particularly the role of automation in offsetting higher production costs and ensuring financial stability. By analyzing these factors, attendees will gain a comprehensive understanding of the nearshoring landscape and its implications for their organizations, as well as insights into strategic decision-making and the future of manufacturing in North America.

Lactoprene® PLLA/TMC Materials for High-Performance Absorbable Implants

PLLA homopolymers have been used for mechanically competent implantable medical devices, although studies have shown significant risks for late-stage biocompatible issues due to the crystalline nature of the material. To address these items, a number of device developers have utilized PLGA-based random copolymers that provide similar initial strength profiles as PLLA, while sacrificing significant losses in creep performance. Poly-Med’s Lactoprene® PLLA/TMC block copolymers are biocompatible alternatives to PLLA with superior performance to PLGA-based materials. Poly-Med’s Lactoprene® formulations have been used in implantable medical devices for over 10 years with no known clinical issues due to material composition. Lactoprene® can be converted via a variety of processing methods, including but not limited to extruded monofilaments and multifilaments, knitted surgical meshes, braided sutures, electrospun nanofibrous fabrics, 3D printing and injection molding.

Sandvik’s Metal Powders and Machining Solutions for the Medical Industry

Sandvik Additive Manufacturing – Booth 927

Sandvik’s comprehensive offerings for the medical industry include high-quality metal powders (e.g. Stainless, Cobalt and Titanium alloys) and advanced machining solutions, driving innovation in manufacturing. Sandvik Osprey’s metal powders are known for their high quality, purity and consistent properties, making them ideal for additive manufacturing and metal injection moulding.

Technological advancements in additive manufacturing have led to the potential for utilizing larger powder-bed layer thicknesses, increasing productivity in laser powder bed fusion (LPBF). By increasing layer thickness, coarser powder particle size distribution (PSD) can be employed, driving a shift towards a more sustainable process chain and reinforcing the business case for additive manufacturing. Results from a study that evaluates the effect of larger layer thickness (90 µm) using recommended PSD (15 to 45 µm) and coarser PSD (45 to 90 µm) on the surface characteristics, heat-treated microstructure and mechanical properties of Ti64 components will be presented.

Solar Atmospheres: Precision Vacuum Heat Treating for the Medical Industry

Solar Atmospheres is a quality-driven commercial heat treater specializing in vacuum processing to deliver clean, bright results with minimal to no distortion. These high-precision outcomes are critical to the medical industry, where consistency and reliability are paramount. With over 40 years of expertise, we have earned numerous corporate prime approvals by consistently meeting stringent requirements. Many medical standards stem from the aerospace industry, where we have maintained compliance for decades. The medical manufacturing process is highly complex, and we excel in providing problem-solving capabilities through advanced vacuum heat treatment. We process common medical hardware, including: stents, catheterization wires, implantable devices for electrical stimulation, various joint implants, and more.

X-ray Irradiation: An Alternative to Gamma for Medical Devices

Ionizing radiation technologies, including gamma, electron beam and X-ray, are widely recognized for their use in terminal sterilization and material modification for healthcare products. In this presentation, we will review the key considerations for transitioning between these technologies, including a risk-based assessment and approaches to validating a new healthcare product in compliance with ISO 11137, AAMI TIR104, and related standards. Additionally, we will discuss recent advancements and expansions in processing capacity that make X-ray a viable complementary or alternative ionizing technology, particularly when photon-based solutions are preferred. An introduction to the new X-ray processing system in Libertyville, Illinois, and increased global expansions in X-ray at STERIS will also be shared.